Back to

products menu

Abrasive Wheels for precision grinding

Centerless bar grinding

Operation scheme

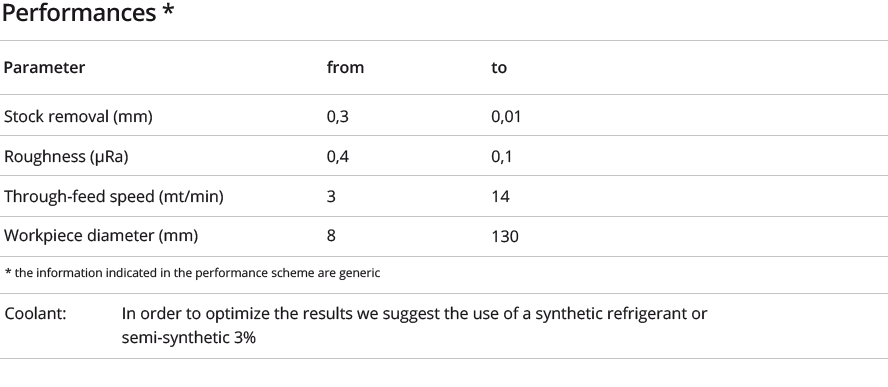

Siapi Smartech is specialized since more than 30 years in precision grinding and is able to offer its customers a range of specific products for bar grinding. For this application, our R&D department has developed specific grinding wheels based on various parameters: type of machine and model, machine power and coolant in use are only part of the information necessary for our technicians for their evaluations. The types of grinding wheels most used in this application are produced in rubber and/or resin bond for the roughing operation and in rubber and cork bond for the semi-finishing and finishing operations. The rubber is able to absorb the micro-vibrations generated by the machine and guarantees excellent surface roughness, avoiding the optical spirals on the pieces exiting the machine. The long life is guaranteed by the self-dressing effect, together with a narrow range of finish, roundness and dimensional tolerance.

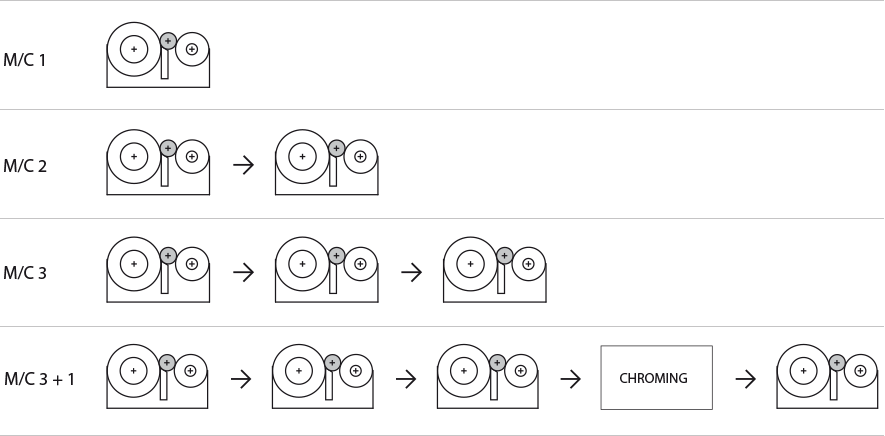

The multiple grits technology allows to combine removal and roughness by reducing the amount of passes, which allows the use of fewer grinding machines used with consequent savings in both labor and energy.

Our technicians specialized in centerless grinding, after a careful analysis of the processes on the production lines, are able to design a "CUSTOM MADE" tool for every specific situation, thus reducing the incidence of the cost per piece.

According to the specification, the following materials can be processed: hardened steel, tempered steel, chromed steel, stainless steel. In some cases the same specification is able to work on multiple materials.

Features and advantages of Siapi Smartech wheels for bar grinding

Self-dressing

Multiple grits

Long life

Self-dressing

Multiple grits

Long life

Excellent finish degree of the worked surface

Most common production cycles

Most common production cycles

Rubber and cork bonded wheel in multiple grits

Related Products

Available Shapes

Example of working cycle

M/C 1

Rubber Bonded

wheel grit 60

M/C 2

Rubber and cork bonded

wheel grit 150 - 220

M/C 3

Rubber and cork bonded

wheel grit 280 - 300

Related Products

Rubber Bonded Grinding Wheels

Resin Bonded Grinding Wheels

Vitrified Bonded Grinding Wheels

Rubber Bonded Regulating Wheels

Specific dressing tool for any binder